Comprehensive Guide to Briggs and Stratton Engine 123K02 Breather Hose Cleaning

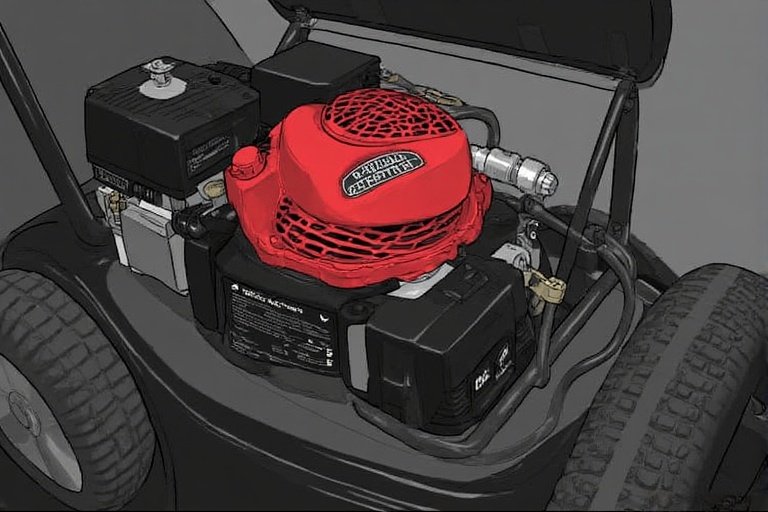

Maintaining a Briggs and Stratton engine 123K02 involves regular upkeep to ensure optimal performance and longevity. One critical yet often overlooked component is the breather hose, which plays a vital role in regulating crankcase pressure and preventing oil leaks. Proper Briggs and Stratton engine 123K02 breather hose cleaning is essential to keep your engine running smoothly, whether it powers a lawnmower, pressure washer, or other outdoor equipment. This guide provides a detailed, step-by-step approach to cleaning the breather hose, ensuring your engine remains in top condition.

Understanding the Breather Hose in the Briggs and Stratton Engine 123K02

The breather hose in a Briggs and Stratton engine 123K02 is a small but crucial component of the engine’s crankcase ventilation system. It allows excess pressure and gases to escape from the crankcase while preventing contaminants like dust and debris from entering. Over time, the breather hose can become clogged with oil residue, dirt, or carbon deposits, which can impair engine performance. Regular Briggs and Stratton engine 123K02 breather hose cleaning helps maintain proper ventilation, reduces oil consumption, and prevents issues like engine stalling or poor idling.

Neglecting Briggs and Stratton engine 123K02 breather hose cleaning can lead to increased crankcase pressure, which may cause oil leaks, seal damage, or reduced engine efficiency. By understanding the role of the breather hose, you can appreciate why routine cleaning is a key part of engine maintenance.

Why Cleaning the Breather Hose is Important

The breather hose in the Briggs and Stratton engine 123K02 ensures that the crankcase remains properly ventilated. A clogged breather hose can disrupt this balance, leading to several problems:

- Increased Crankcase Pressure: A blocked breather hose traps gases, increasing pressure inside the crankcase, which can force oil past seals and gaskets.

- Reduced Engine Performance: Poor ventilation affects combustion efficiency, leading to rough idling or power loss.

- Oil Contamination: A clogged hose can cause oil to mix with debris, reducing lubrication quality and accelerating engine wear.

- Environmental Impact: Excess oil leakage due to a faulty breather hose can harm the environment.

By prioritizing Briggs and Stratton engine 123K02 breather hose cleaning, you can prevent these issues and extend the life of your engine.

Tools and Materials Needed for Briggs and Stratton Engine 123K02 Breather Hose Cleaning

Before starting the Briggs and Stratton engine 123K02 breather hose cleaning process, gather the following tools and materials:

- Screwdriver Set: To remove engine covers and access the breather hose.

- Socket Wrench Set: For loosening bolts securing the breather assembly.

- Clean Rags: To wipe down components and clean up spills.

- Degreaser or Carburetor Cleaner: To dissolve oil and carbon buildup in the breather hose.

- Compressed Air Can: To blow out debris from the hose.

- Replacement Breather Hose (Optional): If the hose is damaged, have a replacement ready (part number 691923 for the Briggs and Stratton engine 123K02).

- Safety Gear: Gloves and safety glasses to protect against chemicals and debris.

- Small Brush: A toothbrush or pipe cleaner for scrubbing the hose interior.

- Container: To catch any spilled oil or cleaner.

Having these tools on hand ensures a smooth and efficient Briggs and Stratton engine 123K02 breather hose cleaning process.

Step-by-Step Guide to Briggs and Stratton Engine 123K02 Breather Hose Cleaning

Follow these detailed steps to perform Briggs and Stratton engine 123K02 breather hose cleaning effectively:

Step 1: Prepare the Engine

Ensure the engine is turned off and cooled down to avoid burns or injury. Disconnect the spark plug wire to prevent accidental starts. Place the equipment on a flat surface and clean the exterior to avoid introducing dirt into the engine during disassembly.

Step 2: Locate the Breather Hose

The breather hose in the Briggs and Stratton engine 123K02 is typically connected to the breather assembly, located near the air cleaner or carburetor. Refer to the engine’s manual (available from the Briggs & Stratton website) to identify the exact location. The breather hose is a small, flexible tube, often made of rubber or plastic, connected to the crankcase.

Step 3: Remove the Breather Hose

Using a screwdriver or socket wrench, carefully remove the screws or bolts securing the breather assembly. Gently disconnect the breather hose from its fittings, taking care not to damage the hose or surrounding components. If the hose is brittle or cracked, consider replacing it during the Briggs and Stratton engine 123K02 breather hose cleaning process.

Step 4: Inspect the Breather Hose

Examine the breather hose for signs of wear, such as cracks, hardening, or excessive oil buildup. A damaged hose should be replaced to ensure proper crankcase ventilation. If the hose appears intact, proceed with cleaning.

Step 5: Clean the Breather Hose

- Soak the Hose: Place the breather hose in a container with degreaser or carburetor cleaner to loosen oil and carbon deposits. Let it soak for 10-15 minutes.

- Scrub the Interior: Use a small brush or pipe cleaner to scrub the inside of the hose, removing stubborn debris. Rinse the hose with clean water or additional cleaner to ensure it’s free of residue.

- Blow Out Debris: Use compressed air to blow through the hose, ensuring it’s completely clear. This step is critical for effective Briggs and Stratton engine 123K02 breather hose cleaning.

Step 6: Clean the Breather Assembly

While the hose is soaking, inspect and clean the breather assembly. Remove any dirt or oil buildup using a clean rag and degreaser. Ensure the breather valve (if present) moves freely and is not stuck.

Step 7: Reinstall the Breather Hose

Once the hose and assembly are clean and dry, reattach the breather hose to its fittings. Secure the breather assembly with the appropriate screws or bolts, ensuring a tight seal to prevent leaks.

Step 8: Test the Engine

Reconnect the spark plug wire and start the engine. Listen for unusual noises and check for oil leaks around the breather hose. A properly cleaned breather hose should result in smoother engine operation and stable idling.

Tips for Effective Briggs and Stratton Engine 123K02 Breather Hose Cleaning

- Regular Maintenance: Perform Briggs and Stratton engine 123K02 breather hose cleaning every 50-100 hours of engine operation or at least once per season to prevent buildup.

- Check Related Components: While cleaning the breather hose, inspect the air filter (part number 491588S) and spark plug (part number 796112S) for wear and replace them if necessary.

- Use OEM Parts: If replacing the breather hose, use genuine Briggs & Stratton parts to ensure compatibility and performance.

- Avoid Over-Cleaning: Excessive use of harsh cleaners can degrade the hose material, so follow manufacturer recommendations.

Common Issues and Troubleshooting

If you encounter problems during or after Briggs and Stratton engine 123K02 breather hose cleaning, consider these troubleshooting tips:

- Engine Still Leaks Oil: A persistent oil leak may indicate a damaged breather hose or gasket. Replace the hose (part number 691923) or the breather gasket (part number 692249).

- Rough Idling: A clogged carburetor or dirty air filter may cause idling issues. Clean or replace these components as needed.

- Breather Hose Won’t Come Clean: If the hose remains clogged after cleaning, replace it to restore proper ventilation.

Conclusion

Regular Briggs and Stratton engine 123K02 breather hose cleaning is a simple yet effective way to maintain your engine’s performance and extend its lifespan. By following the steps outlined in this guide, you can ensure proper crankcase ventilation, prevent oil leaks, and keep your equipment running smoothly. Incorporating Briggs and Stratton engine 123K02 breather hose cleaning into your routine maintenance schedule will save you time and money by avoiding costly repairs. With the right tools and a bit of care, this task is straightforward and rewarding for both novice and experienced users.

FAQs

How often should I perform Briggs and Stratton engine 123K02 breather hose cleaning?

You should clean the breather hose every 50-100 hours of operation or at least once per season. Regular cleaning prevents buildup and ensures optimal engine performance.

Can I use any cleaner for Briggs and Stratton engine 123K02 breather hose cleaning?

Use a degreaser or carburetor cleaner specifically designed for small engines. Avoid harsh chemicals that may damage the hose material.

What happens if I don’t clean the breather hose in my Briggs and Stratton engine 123K02?

A clogged breather hose can cause increased crankcase pressure, oil leaks, and reduced engine efficiency. It may also lead to premature wear of engine components.

Should I replace the breather hose during Briggs and Stratton engine 123K02 breather hose cleaning?

If the hose is cracked, brittle, or heavily clogged, replace it with a genuine Briggs & Stratton breather hose (part number 691923) to ensure proper function.

Where can I find a replacement breather hose for my Briggs and Stratton engine 123K02?

Replacement parts, including the breather hose, can be purchased from the Briggs & Stratton online store, Sears PartsDirect, or authorized dealers. Always verify the part number (691923) for compatibility.

Can I perform Briggs and Stratton engine 123K02 breather hose cleaning without professional help?

Yes, with the right tools and this guide, most users can clean the breather hose themselves. Always follow safety precautions and consult the engine manual if unsure.

By adhering to this comprehensive guide, you’ll master Briggs and Stratton engine 123K02 breather hose cleaning and keep your engine in peak condition for years to come.